Content

In evaporative cooling systems, honeycomb cooling pads usually have higher cooling efficiency, more stable heat exchange performance, and longer service life than traditional structured cooling pads, and perform better in most application scenarios. However, “better” is not an absolute concept; it depends on the application environment, system configuration, and usage requirements. Overall, honeycomb cooling pads have become the mainstream configuration solution in modern evaporative cooling equipment.

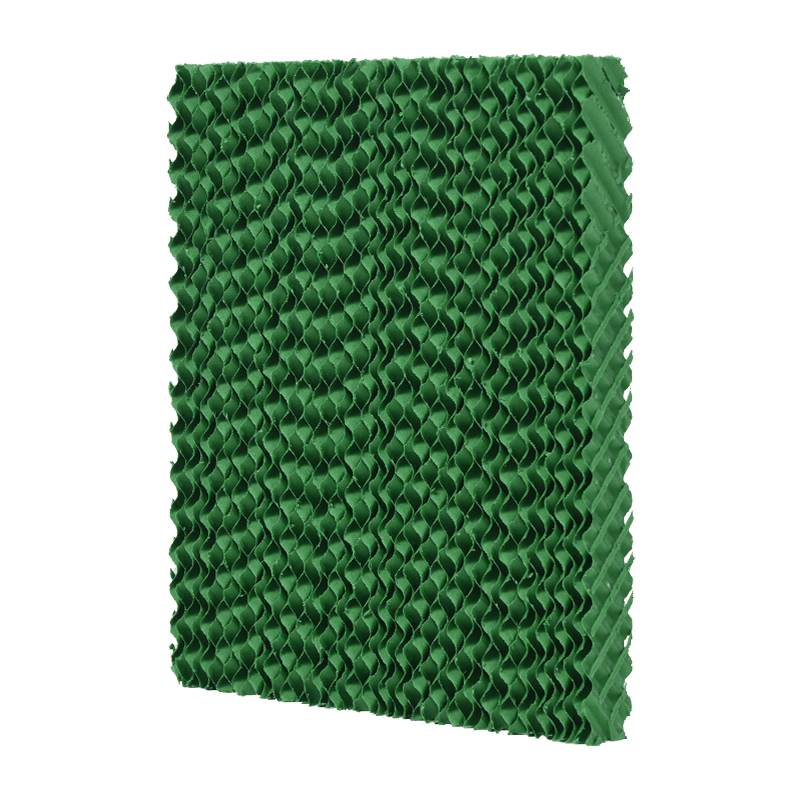

Features of honeycomb cooling pads

Honeycomb cooling pads adopt a regular three-dimensional honeycomb structure design: uniform porous arrangement, more even water distribution, more stable air channel structure, lower air flow resistance, and larger water film coverage area. Compared with traditional corrugated cooling pads or fiber cooling pads, honeycomb cooling pads have a significantly higher heat exchange area per unit volume.

The advantages of honeycomb cooling pads are reflected in: large contact area, uniform and continuous water film, stable air flow channels, and high evaporation efficiency. Under the same air volume and water volume conditions, the cooling efficiency of honeycomb cooling pads can usually increase by 10%–20%, and the advantage is more obvious in high-temperature environments.

The regular structure of honeycomb cooling pads brings: lower air resistance, smoother airflow passage, lower fan load, and reduced overall system energy consumption. This not only improves the cooling effect, but also reduces fan power consumption, achieving system-level energy saving.

Compared with ordinary cooling pads: the honeycomb structure has strong anti-collapse ability, is not easy to deform, not easy to break, has strong resistance to water-soaking aging, and high stability in long-term humid environments. Under normal use conditions, the service life of honeycomb cooling pads can reach 3–5 years, which is significantly better than ordinary fiber cooling pads.

Honeycomb cooling pads perform more stably in water circulation systems: not easy to clog, easy to clean, not easy to scale, strong resistance to microbial growth, and more suitable for industrial circulating water environments and long-term operation systems.

Performance comparison with other types of cooling pads

| Comparison dimension | Honeycomb cooling pad | Corrugated cooling pad | Fiber cooling pad |

| Heat exchange efficiency | High | Medium | Low |

| Air resistance | Low | Medium | High |

| Structural stability | High | Medium | Low |

| Service life | Long | Medium | Short |

| Maintenance cost | Low | Medium | High |

| Application scenarios | Industrial / commercial | Civil use | Temporary scenarios |

Honeycomb cooling pads are widely used in: evaporative air coolers, industrial cooling systems, factory cooling systems, livestock breeding ventilation systems, greenhouse cooling systems, data center auxiliary cooling, commercial place cooling equipment. These scenarios have high requirements for cooling efficiency, stability, and durability.

In the following scenarios, ordinary cooling pads may be more cost-effective: short-term use projects, temporary cooling systems, low-budget projects, small equipment, low-intensity operating environments.

Selection practical suggestions:

High-temperature and high-humidity environments → prioritize honeycomb cooling pads

Long-term operation systems → prioritize honeycomb cooling pads

Industrial-grade applications → must choose honeycomb structure

Temporary cooling projects → ordinary cooling pads optional

Low-load systems → prioritize cost-effectiveness

From an engineering performance perspective, honeycomb cooling pads are generally superior to other types of cooling pads in cooling efficiency, system stability, energy consumption control, and service life, and are the preferred solution in modern evaporative cooling systems.

English

English 中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt

CONTACT US

CONTACT US