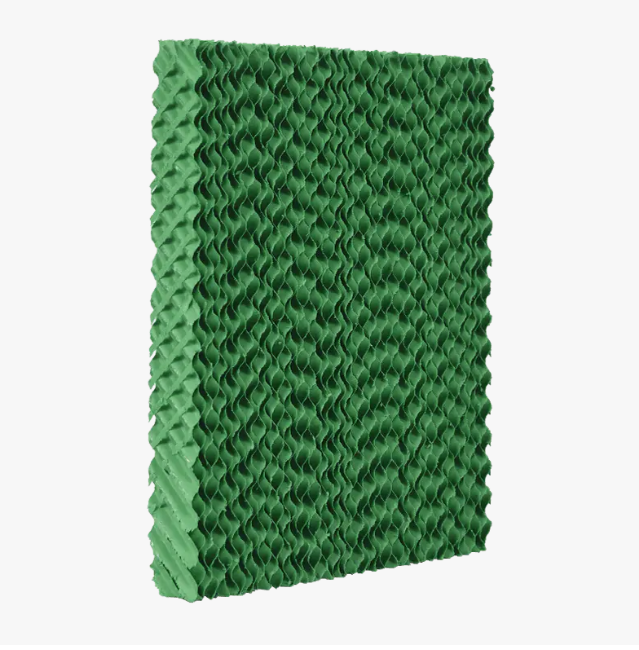

An evaporative cooling pad, commonly known as a wet curtain, is a core component of modern high-efficiency cooling systems. Whether used in agricultural greenhouses, livestock sheds, or industrial plant ventilation, its stable and efficient cooling performance relies on its unique material composition. So, what materials make this crucial cooling medium?

I. The Key Player: Special Highly Absorbent Cellulose Paper

The core raw material for the vast majority of high-quality evaporative cooling pads is special cellulose paper. This paper is not ordinary paper, but a porous material produced through a special process and high-pressure lamination.

1. Selection of High-Quality Raw Materials

The cellulose paper used to manufacture wet curtains is typically derived from imported long-fiber wood pulp. The long fibers give the paper excellent wet stiffness (i.e., structural strength in a wet state), ensuring that the cooling pad will not collapse or deform under prolonged immersion in water and high-speed airflow, thus maintaining stable pressure loss and ventilation.

2. Special Chemical Treatment

To enhance the durability and functionality of the cooling pad, the cellulose paper undergoes multiple impregnation processes during production:

Phenolic Resin/Other Polymer Resins: The resin forms the "skeleton" of the evaporative cooling pad. Through impregnation and curing, the resin solidifies the loose paper fibers into a robust honeycomb structure, significantly improving the cooling pad's water resistance, corrosion resistance, and structural strength.

Preservatives and Algaecides: In humid environments with frequent water flow, algae and bacteria easily proliferate. High-quality cooling media incorporate environmentally friendly algaecides and preservatives, effectively inhibiting microbial growth, extending the cooling system's lifespan, and maintaining air freshness.

II. Unique Honeycomb Structure Design

While the material composition is important, its physical structure is key to achieving efficient cooling. Evaporative cooling pads are renowned for their unique honeycomb structure, constructed from multiple layers of corrugated cellulose paper, providing a vast effective evaporation surface area.

Common corrugated angle designs aim to optimize the contact time between air and water, achieving maximum cooling efficiency while controlling air resistance (pressure loss) within a reasonable range. This structure ensures that air flows evenly across the evaporative cooling pad, carrying away heat.

III. Summary: The Source of Durability and Efficiency of Evaporative Cooling Pads A high-quality evaporative cooling pad consists of several key components that work together to ensure its efficient cooling performance and long service life:

Highly Absorbent Cellulose Paper: This is the core cooling medium, its main function being to store moisture and provide a large evaporation surface area. It is typically made from long-fiber wood pulp, ensuring excellent water absorption and moisture retention capabilities.

Specialty Resins: Such as phenolic resins. Their core function is structural curing, shaping the cellulose paper into a robust honeycomb structure and significantly improving wet stiffness and structural strength, ensuring excellent water resistance and corrosion resistance of the cooling pad in a wet state.

Anti-corrosion/Anti-algae Additives: These are chemical additives used to inhibit the growth of microorganisms. Their presence is crucial for maintaining the hygiene of the cooling system and preventing the growth of algae and bacteria, thereby effectively extending the service life of the cooling pads and making maintenance easier.

English

English 中文简体

中文简体 عربى

عربى Tiếng Việt

Tiếng Việt

CONTACT US

CONTACT US